Inventory Management + Routing: The Complete Guide to Optimizing stock, Warehouses, and Delivery Operations

For years, most distribution teams have treated inventory management and routing as two separate worlds. The warehouse counts, picks, and replenishes; drivers handle routes, customers, and on-the-road decisions.

But the most efficient distribution companies have figured something out something critical: inventory and routing are directly dependent on each other, and when they’re connected, everything becomes easier, faster, and far more accurate.

This guide walks through how distribution operations tend to work today, where friction usually appears, why more companies are moving toward integrated systems, and what a truly connected inventory + routing workflow looks like in practice. We’ll also explore how bMobile makes this possible and what a simple roadmap for improving your operations might look like.

By the end, you’ll have a clear picture of why the future of distribution belongs to businesses that unify the warehouse and the road, and how doing so unlocks big wins across your entire operation.

The relationship between inventory management and routing

Inventory management and routing aren’t adjacent functions inside a distribution operation. They are part of the same continuous flow of information, decisions, and movement.

Inventory decides what can be delivered, when it can be delivered, and in what quantities. Routing determines how that inventory moves (because inventory doesn’t just stop mattering once the product leaves the warehouse), which customer receives it first, and how efficiently it reaches its destination. Every route is, at its core, a plan for moving inventory through space and time.

Together inventory management and routing are two halves of the same process. One determining availability, and the other determining execution.

How distribution operations typically work today

For many distributors running anywhere from 5 to 30 trucks, operations are organized across multiple specialized systems. Orders are entered in an order management or ERP system. Inventory is tracked separately. The warehouse uses pick tickets or a WMS to prepare loads. Routes are planned in a dedicated routing tool. Drivers use a mobile app, paper invoices, or delivery paperwork once they leave the warehouse. Each system is responsible for its own part of the operation.

Updates are captured where they occur and passed along later, often at set checkpoints rather than continuously. This structure is common across distribution operations and has been the standard way of managing warehouses and fleets for years.

In many cases, this model is exactly what allowed businesses to grow in the first place. It works well when volume is manageable and teams are small enough to stay aligned through experience and communication. But as routes multiply, order counts rise, and service expectations increase, the model isn’t designed to scale with the business. Growth begins to depend more on people compensating for gaps than on the systems supporting the operation.

Where friction happens (and why its costs you)

Friction shows up the moment systems and teams stop communicating. It starts with small things like a stock count that’s off by a couple units and snowballs into late deliveries, customer complaints, and expensive reroutes.

When inventory isn’t accurate, the warehouse picks the wrong products. When routes are built without real-time inventory data, drivers leave unprepared. When proof-of-delivery isn’t synced automatically, the inventory team relies on outdated information. This kind of fragmentation makes operations reactive instead of proactive. Instead of planning ahead, teams spend their time fixing mistakes.

For distributors handling perishable products, that friction has an added cost: time. Delays, rework, and inefficient routing keep products sitting in inventory longer than planned or moving through the network more slowly than intended. Research in perishable supply chains shows that reducing the average time products spend in inventory can cut spoilage costs by up to 40%, highlighting how closely operational coordination is tied to waste reduction.

Over time, these inefficiencies drain profitability. They also erode customer trust, while internal teams lose confidence in the system because it consistently produces surprises instead of clarity.

Why more companies are moving toward integrated systems

To eliminate these recurring problems, distribution companies are shifting toward integrated systems that connect inventory management, warehouse operations, routing, dispatching, and proof of delivery all into one real-time ecosystem. Integrated systems solve the single biggest problem in distribution: information delay.

Instead of data being manually updated hours later (or not at all), the warehouse, the office, dispatch, and drivers all operate from the exact same information at the exact same time. Stock levels update instantly. Pick lists adjust instantly. Routes refresh instantly. Deliveries update inventory instantly.

This kind of connectivity with real-time analytics turns a complicated distribution workflow into a streamlined, predictable machine.

One study of real-time analytics adoption showed delivery times improved by 35% and on-time shipment rates improved by 25%, while stock-out rates declined by 42% after real-time data integration was introduced.

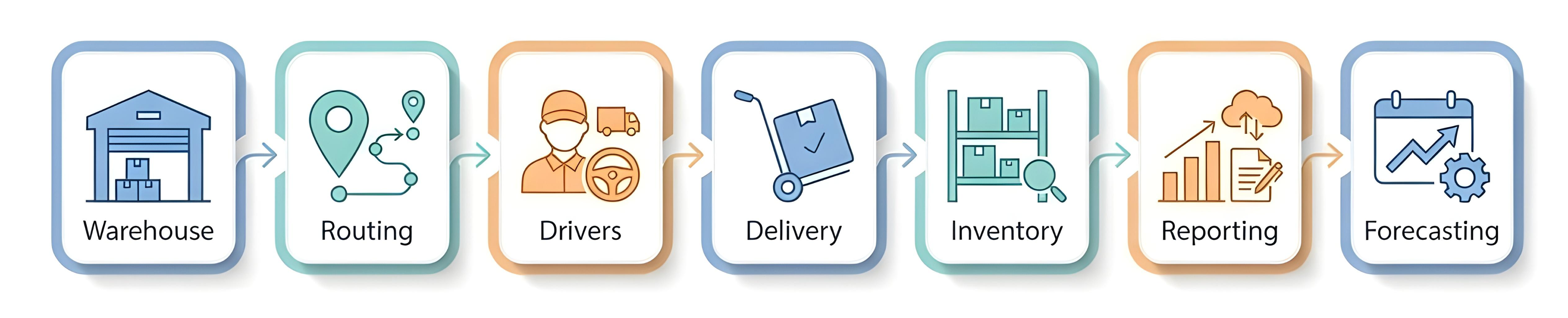

What a Connected Inventory + Routing Workflow Looks Like

A connected workflow begins the moment an order comes in. Inventory management software checks stock levels right away, so there’s no guesswork. The warehouse receives the correct pick tasks, and as items are scanned, inventory updates instantly. Those confirmed picks flow directly into the route optimization software, which builds routes based on what’s available instead of what the team hopes will be available in the inventory.

Dispatch sees a live route plan. Drivers receive up-to-date instructions and accurate load details. Customers receive reliable delivery windows. And once a delivery is completed, proof-of-delivery syncs immediately, adjusting inventory in real time.

Every piece of the process supports the next piece. No more rewriting pick tickets. No more calling drivers halfway through a route. No more end-of-day reconciliation nightmares.

This is what modern distribution looks like. And this is why more businesses are moving in this direction.

The advantages of connecting inventory and routing

When inventory and routing work together, distribution companies see improvements across the board:

- Faster, more accurate deliveries: With real-time inventory feeding directly into routing, trucks leave with the right products every time. This cuts down on repeated deliveries, last-minute scrambles, wasted miles, and drastically improves on-time delivery rates.

- Lower operational costs: Optimized routes, correct loads, and fewer errors lead to reduced fuel usage, fewer driver hours, less overtime, and less warehouse labor spent fixing mistakes. This creates measurable savings across the entire supply chain.

- Better inventory accuracy: Because every pick, scan, return, and delivery, updates the system automatically; stock levels remain accurate. Accurate inventory means fewer stockouts, fewer over-orders, and far smoother replenishment cycles.

- More productive warehouse: Pickers aren’t guessing, managers aren’t chasing updates, and the warehouse stays organized instead of reactive. Predictable workflows dramatically increase throughput and reduce congestion.

- Stronger customer experience: Customers receive accurate ETAs, complete orders, and real-time updates. A connected workflow improves communication and reliability, two factors that turn one-time buyers into loyal accounts.

- Scalability: When your inventory, warehouse, routing, and delivery systems are connected, growth becomes effortless. There’s no manual data entry slowing things down, so whether you’re running five trucks or fifty, the workflow scales smoothly without adding complexity.

- End-to-end visibility: Leaders gain a complete picture of how the warehouse, drivers, routes, inventory, and customers all connect. This visibility supports smarter decisions about staffing, purchasing, and expansion.

How bMobile enables this connected workflow

bMobile is built specifically for distribution companies that want to unify their operations. Instead of storing data in separate software tools that don’t talk to each other, bMobile creates a single ecosystem that ties inventory management, warehouse operations, route optimization, delivery management, and proof-of-delivery together seamlessly.

Warehouse scans update inventory instantly. Routes are generated based on real stock levels. Drivers receive everything they need on one app from load lists, order details, optimized routes, to delivery confirmations. And every delivery gets fed back into the system automatically, so the business always knows exactly what happened and what needs to happen next.

This real-time, end-to-end workflow gives distribution teams the accuracy, reliability, and visibility they’ve always needed but could never achieve with disconnected tools.

bMobile is designed specifically for the realities of distribution, where timing and accuracy matters, and small errors create big downstream problems. What sets bMobile apart is that it doesn’t just replace one part of your workflow; it connects every part.

bMobile combines inventory management, WMS functions, route optimization, delivery management, and proof-of-delivery into one synchronized platform. This means your warehouse, routes, drivers, office staff, and customers all rely on the same real-time data, every second of the day.

When an order comes in, bMobile instantly checks inventory availability. The warehouse receives accurate pick tasks that update as soon as items are scanned. Route optimization software builds the most efficient routes based on actual, confirmed stock. Dispatchers can make adjustments on the fly, and drivers see updates immediately on their mobile device.

On the road, bMobile’s route manager tools provide turn-by-turn navigation, intelligent real-time adjustments, live driver tracking, and accurate ETAs. Once a delivery is completed, digital proof of delivery (signatures, photos, timestamps) syncs instantly, updating inventory, closing out the order, and triggering the invoice.

This creates a closed loop with all the processes in one system, with no manual re-entry and no delays.

A simple roadmap for optimizing your workflow

Improving distribution operations doesn’t require ripping out everything at once. In fact, the most successful teams approach optimization in stages, focusing first on fundamentals and then layering in connectivity.

The smartest starting point is simply improving inventory accuracy, because without reliable stock data, every other part of the workflow becomes harder. Once your inventory is consistent and trustworthy, the next step is connecting the warehouse to that system so every pick, scan, and adjustment updates in real time.

From there, integrating routing and dispatch management creates the next big lift in efficiency. Drivers leave with complete and accurate loads, routes stay optimized, and customers receive more reliable delivery windows. Finally, closing the loop with real-time proof of delivery ensures your forecasting, purchasing, accounting, and operations teams always have dependable, up-to-date information to work from.

Platforms like bMobile are designed to support this kind of step-by-step evolution. Teams can start by replacing the part of the operation where they feel the most pressure without having to overhaul everything at once.

As additional pieces are brought into the same platform, those workflows begin to connect naturally. Inventory informs routing. Warehouse activity feeds delivery plans. Proof of delivery updates stock and orders automatically. Over time, what starts as a targeted improvement becomes a fully integrated system that’s easier to manage, more accurate, and far more scalable.

By taking it step by step, your workflows become more predictable, your teams stay aligned, and your customers enjoy a noticeably smoother experience.

The future of distribution

The future of distribution is already taking shape, and it’s built on connected systems, real-time data, and predictive intelligence. Companies are rapidly adopting tools that blend inventory management, WMS capabilities, route optimization, and delivery management into unified platforms. AI-driven forecasting will help businesses stay ahead of demand. Real-time routing adjustments will become standard. And customers will expect full visibility from warehouse to doorstep.

In this future, the companies that win won’t be the ones who work harder but the ones who work connected. With platforms like bMobile, that future is already within reach.

If you’d like to see how you can stay ahead of the curve with bMobile, you can take a closer look here:

Recent Blog Posts

For years, most distribution teams have treated inventory management and routing as two separate worlds. The warehouse counts, picks, and replenishes; drivers handle routes, customers, and on-the-road decisions.

There is a major shift taking place in route-based distribution. For decades, the role of the route worker was defined by movement: load the truck, deliver the product, collect returns, get a signature and move to the next stop.

If you run a snack or beverage distribution business, you already know the work isn’t glamorous. It starts before sunrise. Trucks have to be loaded, routes planned, shelves filled, invoices written, and sometimes even collected in person.

If you run a snack or bakery distribution business, you know the morning rush is real. Your products come out of the oven or fryer early, and from that moment the clock starts. Shelves at convenience stores, coffee shops, and supermarkets are waiting.

Most bakeries do not lose money because the bread is bad. They lose it in small moments. The rack is empty at 8:15 a.m. Yesterday’s muffins come back as stales. A driver writes a ticket by hand and someone retypes it later. Real-time inventory tracking closes these gaps.

Warehouses are the heartbeat of any distribution or delivery business. If your warehouse is not running smoothly, it shows up everywhere—late deliveries, wrong orders, wasted space, and unhappy customers.

If you run routes, you already know the map never tells the whole story. Demand jumps, a store runs out of stock, a receiving window shifts, and a quick stop eats 25 minutes. We do not sell the shortest path. We coach teams to plan for time, demand, and value, not just miles.

Fresh bread doesn’t wait. Proofing, baking, cooling, packing, and delivery all live on a tight clock. When routes slip, shelves sit empty or returns pile up. If you’ve ever asked why route optimization software keeps coming up in bakery conversations, it’s because margins and freshness windows are decided on the road as much as in the oven.

Picture this: It’s 4 a.m., you’re sipping the first coffee of the shift, and the ovens are warming up. In ten minutes, you have to decide how much dough to mix — but yesterday’s numbers are still buried in a spreadsheet. Sound familiar?

Direct Store Delivery (DSD) lives on narrow margins and fast information. Many distributors rely on QuickBooks for accounting, but still run a separate inventory tool on the side.

Maria Johnson is Director of Sales Operations at a midsize snack distributor that services 1,400 convenience stores across the Southeast.

In today’s distribution world, the way your product gets to the shelf is just as important as the product itself. The path you choose—whether Direct Store Delivery or traditional fulfillment—can shape your margins, customer experience, and even brand visibility in ways that aren’t always obvious at first glance.

Warehouse theft is more than just a pesky inconvenience—it can significantly dent your profits, disrupt your operations, and erode trust among your customers and stakeholders.

Order management systems (OMS) have evolved from basic inventory tools into comprehensive platforms that power modern supply chains.